NewsJuly 26th, 2022

Innovation and success with technology partners

Our success throughout the last 100 years has incorporated the development of strong strategic partnerships with both customers and suppliers to create solutions that gain safety and performance advantages for our customers.

Bradken

Asia Pacific

Link copied

Our success throughout the last 100 years has incorporated the development of strong strategic partnerships with both customers and suppliers to create solutions that gain safety and performance advantages for our customers.

As we take on more digital ways of working, we’re implementing innovative methods to expand our products and service offerings, including new digital technologies to create further opportunities, such as; 3D scanning, ultrasonic scanning, automation, artificial intelligence and robotics.

We’ve built many incredible partnerships globally with suppliers and customers and we are proud to play a part in their story too.

One example of this innovation and success is using FARO technology across our product ranges.

Due to its adaptability, we have incorporated its use across our mineral processing and mobile plant product ranges to efficiently scan, collect and report product data to determine product condition, wear life, reliability and safety, therefore optimising our customer's operational performance.

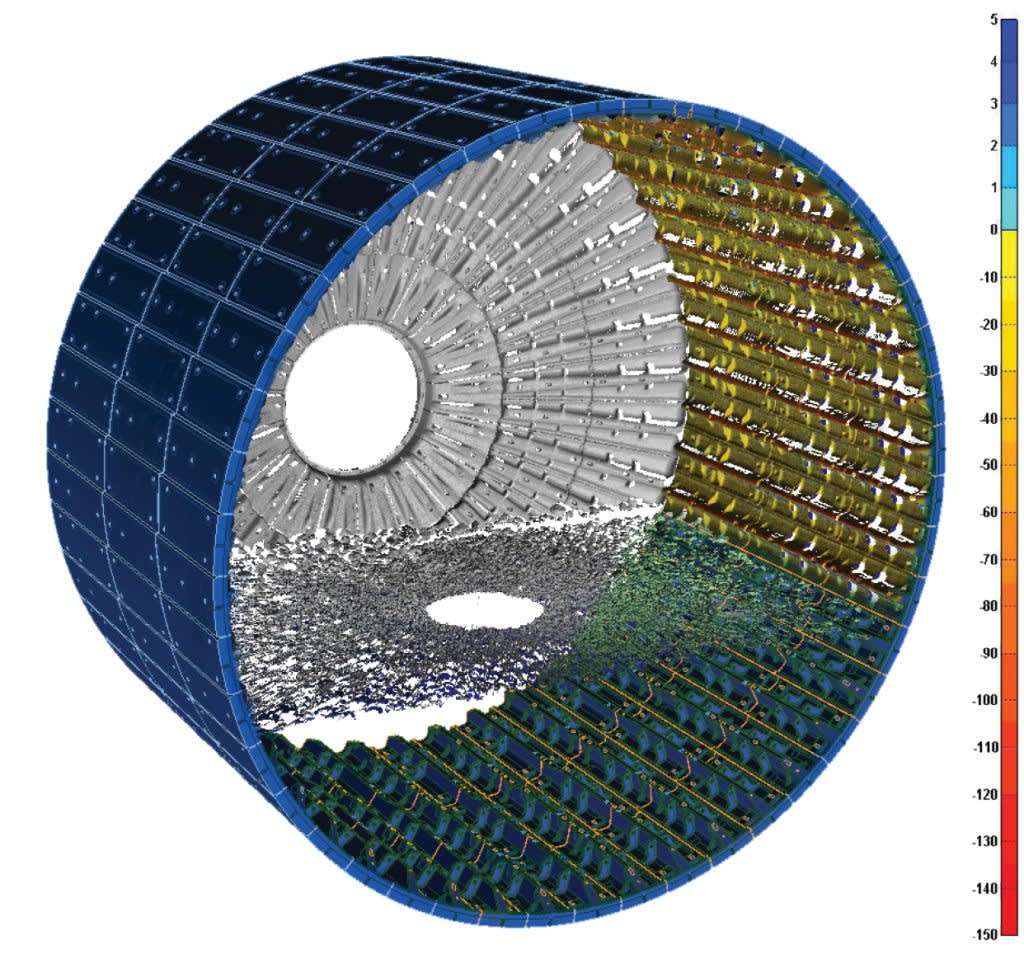

One example of this use is our VisionInsight solutions, which incorporates 3D measuring of mill liners to determine product conditions. With the Bradken team performing 3D laser scans with FARO technology, we can achieve faster data capture and minimize onsite human intervention, where previously personnel must manually measure the liners themselves. This solution provides a safer and more efficient method of monitoring mill liner conditions in this case.

By providing a solution that relies on both ultrasonic and 3D laser scanning, Bradken can generate accurate wear plot imaging and liner profiles, as well as predict a mill liner's longevity of service and high wear zones, enabling the ability to predict mill liner life and change-outs required, improving maintenance efficiency for our customers.

The data is also utilised within Bradken's 3D DEM software to simulate grinding mill performance with the goal to assist in future liner design enhancements, innovations and general liner development.

“For the last nine of their 100 years, Bradken has relied on over 20 FARO® Focus Laser Scanners to assist in the company's wear monitoring and data reporting of mill liners — the protective overlay which shields a mining grinding mill from some of the abrasive and thermal forces generated during the milling (or grinding/pulverizing) of extracted hard rock and metals (namely gold, copper and iron-ore) — thereby extending the life of the mill itself. Recently Vijay Gandhi, the Platform Lead at Bradken, explained how FARO's advanced 3D laser scanner technology, along with its FARO SCENE Software, can scan the working parts of today's most sophisticated mining equipment.” FARO Technology.

Digital Solutions

Vision Insight®

Bradken Vision Insight® services provide 3D Laser wear scanning and reporting to assess your mill performance and assist your condition monitoring teams to plan maintenance and liner replacement activities.

Our digital products may be able to be customised to integrate with your existing technology to provide a great experience for your team.

Find a rep