Power Generation

Bradken serves its Power Generation customers through a wide range of complex castings.

We service customers who operate in the HydroElectric, Nuclear, Combustion and Steam Turbine markets.

We offer services such as but not limited to: modified design, engineering support, pattern making, tooling, castings, machining and fabrication.

In addition to supplying the key traditional energy markets, Bradken is also partnering with customers whose products support sustainable energy sources in Wind, Solar & Water. As demand continues to evolve Bradken has the manufacturing capabilities to work on your developmental projects.

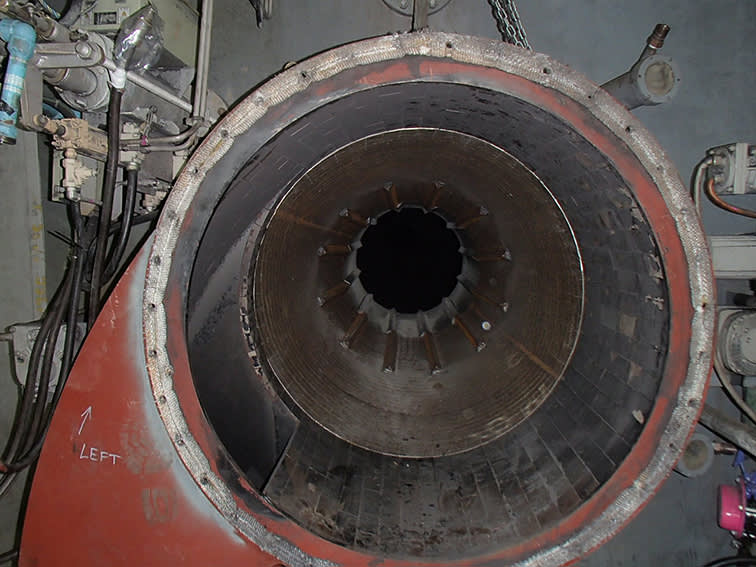

Coal Fired Power Generation Products

Bradken is a major supplier of grinding elements, mill liners and wear protection products used in Coal-fired power generation around the globe.

Hydro Electric Power Generation

Bradken provides high integrity castings for durable performance in hydroelectric power generators. Our foundries are experienced in the manufacture of precision castings including austenitic, duplex, and martensitic stainless steel.

Compressor and Turbine

Bradken is a major supplier of compressor body and turbine castings utilized in a wide range of applications throughout production, processing and pipeline transfer. Whether it is natural gas, oil or another chemical we have the capability and experience to manufacture the size and material casting required.

Case Study

Bradken Supply Chain Support

Learn how Bradken supported a customer by supplying burner barrels within a tight deadline so they could maintain their shutdown schedule when a competitor could not deliver on time.