Weld Overlay Plate

Duaplate® DX

Bradken's Duaplate® DX offers a unique and superior weld overlay product that outperforms conventional Chromium Carbide Overlays (CCO).

Overview

Duaplate DX offers a unique and superior weld overlay product that outperforms

conventional Chromium Carbide Overlays (CCO). Bradken has employed the

latest digital technology in order to create an overlay with a patented chemical

composition that is incredibly resistant to abrasion and can still be used in moderate impact applications. The phenomenal properties of Duaplate DX make it ideal for use in mass sensitive applications that require a light-weight, high performance liner material. Available in large sheet sizes and custom shapes, Duaplate DX can be cut and formed to suit customer requirements.

Manufacture

Duaplate DX is manufactured by fusing a specially formulated powder to a steel base plate. This creates a bi-metallic material with a layer of high performance abrasion resistant overlay combined with a ductile steel base to accommodate

forming and welding.

Microstructure

The unique microstructure of Duaplate® DX consists of a mixture of extremely fine carbides and borides that are surrounded by a predominantly martensitic matrix material. These incredibly hard carbides and borides are approximately 10x smaller than traditional carbides in CCOs, which dramatically increases resistance to wear and further improves impact performance.

Typical Properties

Field trials have confirmed that Duaplate DX improves asset life by 1.8-2.5 times compared to standard CCO plates of the same thickness. Bradken’s Duaplate DX can achieve the same wear life with a thinner, lighter liner, opening opportunity to improve manual handling safety during liner change outs.

Typical Bulk Hardness

850 HV50

Hard Particle Hardness

>1700 HV0.3

Volume Fraction of Hard Particles

~25%-30%

Density

7700 kg/m3

Available Sizes

Duaplate DX can be supplied by Bradken as custom made liner plates or as a 2360 x 2870 sheet. It is available in the following thicknesses:

- 5 on 8

- 8 on 8

- 16 on 8

Used on:

- Vibrating Feeders

- Mobile Equipment

- Bin and Hopper Liners

- Chute Liners

Duaplate® DX Weld Overlay

Duaplate® DX Weld Overlay Manufacturing

Duaplate® DX Weld Overlay Microstructure

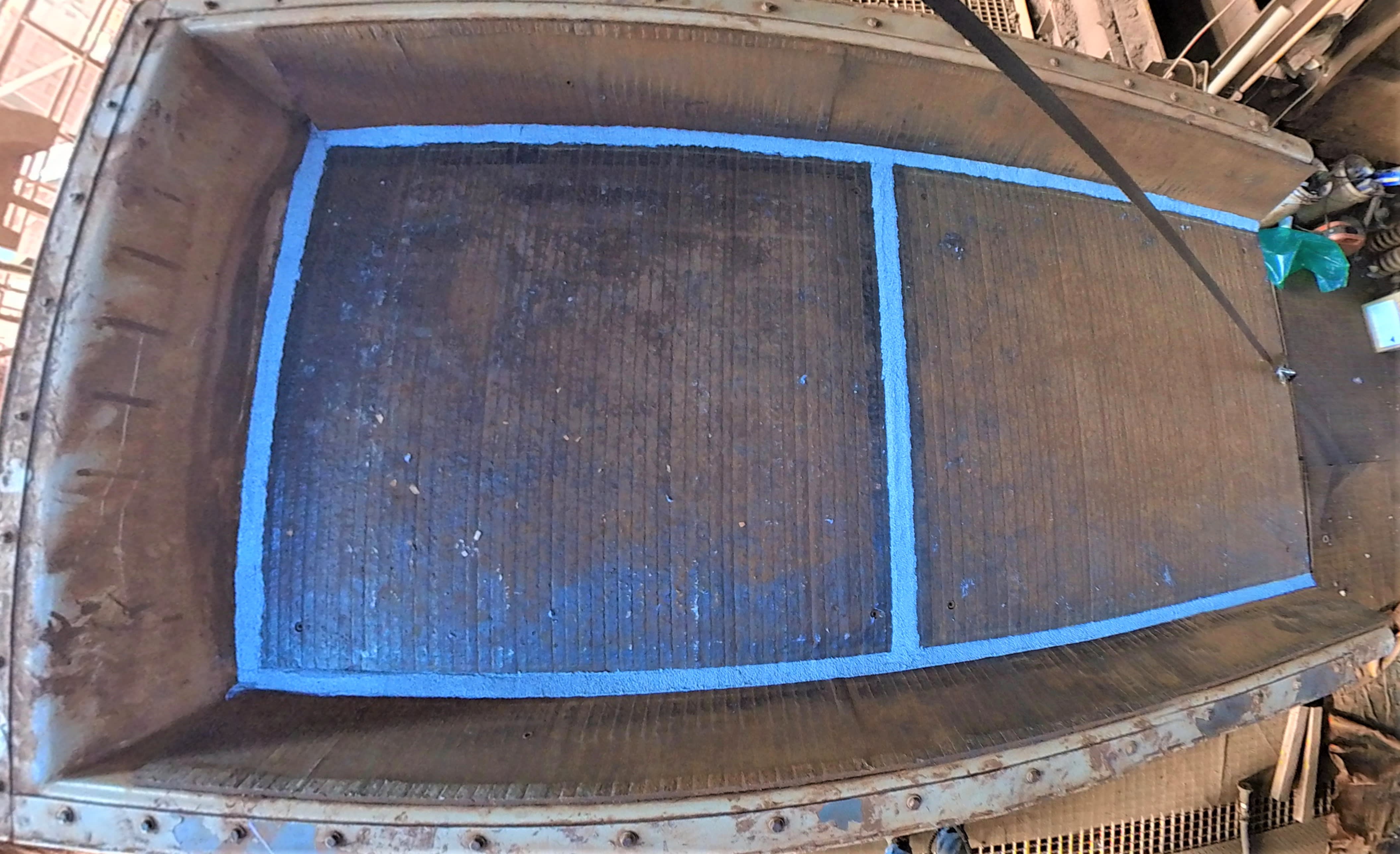

Duaplate® DX Weld Overlay Application

Fortifying Feeder Efficiency: Bradken's Duaplate DX

In the iron-rich expanse of Pilbara, Australia, Bradken redefined feeder durability. By innovating with Duaplate DX, we extended operational life from 13 to 48 weeks. Reverse engineering OEM specs, Bradken introduced a safer, more efficient solution with consolidated liners and reusable lifting points.

Find a rep