Custom Castings

Global suppliers of castings, fabrications & machining services

We work with a variety of cast materials including speciality irons, alloy steels and stainless steel and have the capability to produce castings up to and over 25,000 kilograms or 65,000 pounds.

Structural & Structurally Exposed Steel Castings

Our Engineered Products business, based in North America, are experts in structurally exposed steel, non-destructive testing and understanding the material strength requirements.

Industrial Castings

We bring quality steel castings to our customers with reduced engineering costs and superior first article process. We use our vast industry experience and resources to ensure quality products are delivered to customer specifications.

Heavy Equipment Castings

Bradken serves the Heavy Equipment market through a wide range of capabilities supplying complex large steel castings, patterns, as well as tooling and machining services. In addition to our core manufacturing capabilities Bradken has an extensive amount of experience in fabrication to conversion projects, design support and sub-contractor project management.

Our custom casting capabilities help improve productivity for customers in a number of industries including Mining, Construction, Pulp & Paper, Aggregate, Forestry, Material Handling and General Industrial.

Specialized Markets

Along with supplying the largest steel casting consumption markets in the world Bradken also dedicates a significant amount of resources to identifying, developing and supporting the smaller specialized markets. From one-time prototype castings utilizing rapid foam patterns to the development of a new production line of parts we can provide the best path forward. Our extensive range of materials, size and weight capabilities and technical expertise allow us to support such markets as Structural, Flood Control, Alternative Energy Support, Press and Steel Industry and Food Processing.

Building & Bridge Connection Point Castings

Structurally Exposed Castings

Structural Steel Connection Nodes

Pintle Socket & Base Castings

Sector Gate Castings

Die Block Castings

Molding Component Castings

Component Castings Utilized in Pulp & Paper

Steel Production Component Castings

Steel & Iron Casting supply to third party machine & fabrication shops

Large Press Frame Castings

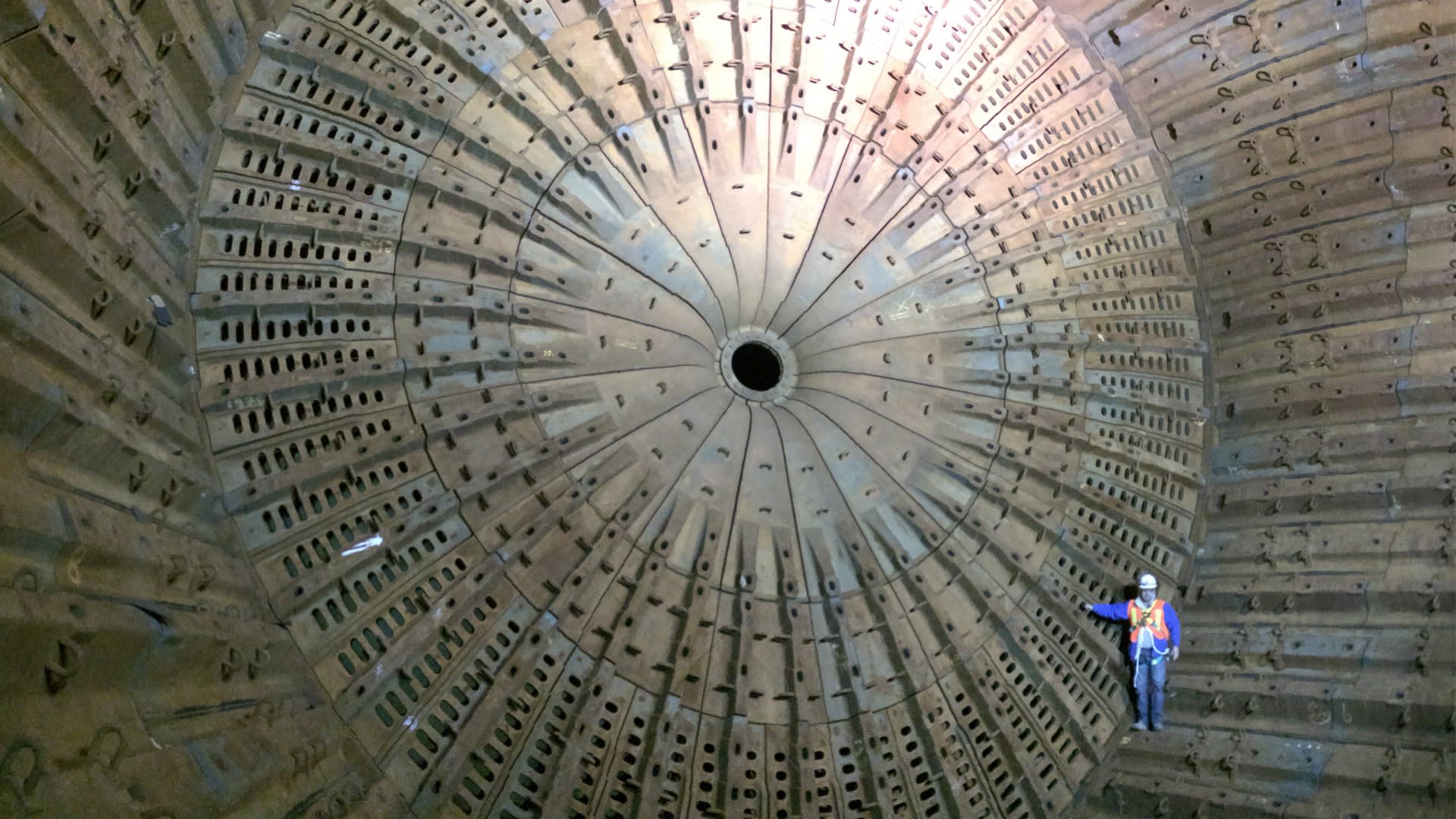

From engineered concept to finished product Bradken provides value for our customers in the Energy market by making high engineered, complex sand molded steel castings, in a range of cast steels. Our capabilities include supplying castings as large as 55,000 lbs (25,000 kg).

Value add offerings include:

Concurrent engineering (fabrication to casting conversions, forging to casting conversions and improved castability)

Pattern making and tooling

Certified ASME nuclear material manufacturer

Complete Non-Destructive Testing (NDT) facilities and Level III certified inspectors

Ancillary services (including machining and sub-assembly)

Understanding and possessing the necessary qualifications is vital in being able to supply the exacting standards of the energy market. Understanding this, our facilities maintain a number of critical certifications and quality systems in addition to numerous customer specific certifications.

Bradken holds the following certifications:

ISO9001

Nuclear certification by ASME, QSC No. 204

ASME – Section III, NCA 3800 2001

DNV approved manufacturer of steel castings

Lloyds register certificate

CGP – Canadian government control goods program

ABS – American bureau of ship building

Navy Nuclear qualified to NAVSEA 250-1500

Approved to manufacture HY-80 and HY-100 castings by the department of the Navy

Off-shore oil & gas certified by numerous OEM’s and countries with material qualified to EN10225 and API RP2Z

In house ASNT level III non-destructive testing specialists

NACE

ASTM

We offer a full complement of testing and inspection services including:

Visual

Dimensional

Microstructure

Charpy impact

Chemical analysis

Ultrasonic testing (UT)

Radiographic testing (RT)

Liquid penetrant testing (LP)

Magnetic particle testing (MP)