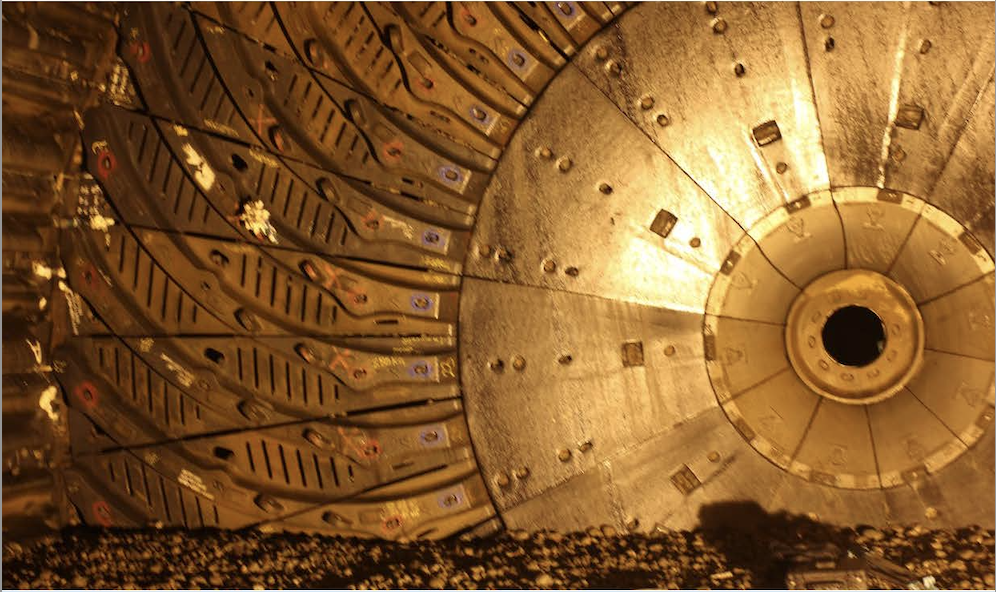

Discharge End Liner System

Bradken is a leader in the design, manufacture and supply of mill liners for SAG/AG Mills, Rod Mills, Ball Mills in the global mineral processing and quarrying industries.

We offer our customers complete wear liner solutions for mills that increase performance, equipment availability and lower maintenance costs.

By utilising the latest technologies, we aim to provide customers with an advanced Mill Liner System that increases mill performance and availability. The optimised design of Bradken’s range of Liner Systems offers a number of advantages including a reduced number of parts, fewer relines, quicker change out and assembly and safer handling ultimately resulting in

a reduction to overall maintenance costs.

Bradken is renowned for innovation, quality, reliability and service.

The Discharge End (DE) pulp lifter is a critical component of autogenous (AG) and semi-autogenous (SAG) grinding mills, having a significant impact on the throughput, efficiency and performance of mills. Underestimating the importance of an optimised liner design in a mill can lead to back-flow and carry-over processes which can ultimately result in high wear, poor liner life and reduced mill throughput.

Installing a Bradken Vortex Discharge End and optimised liner design can lead to significant improvements in mill performance including:

- increased hourly mill throughput

- increased average mill throughput (fresh feed), and

- increased average re-cycle load.

Discharge End Liner System

Discharge End Liner System

Discharge End Liner System

Discharge End Liner System

The Bradken Discharge End Liner System features;

Bradken Bullnose®discharge cones

Manufactured from superior composite wear materials to extend wear

life of the liners and reduce the overall weight by 40% over steel products.

Bullnose® discharge cone system reduces the relining times by 50% to maximise

mill availability.

Discharge grate slot analysis is carried out across all grate designs to optimize open

area, recycle size and product passing performance

Super Vortex®

Grate cover the full depth of the charge to maximize grate open area and mill

throughput exposure

Large One-piece Super Vortex® curved pulp lifters generate maximum flow dynamics during discharge of ore and slurry

Discharge End Liner System Components

Whitepapers

Mill Optimisation Whitepaper

This whitepaper outlines the approach used to identify and implement design changes utilised in the Aktogay 40 ft SAG Mill Lining System. Explore our summary of the operational performance improvements and the future design initiatives being investigated.

Find a rep