MillSafe® Bolting

Bradken’s MillSafe® Bolting System is a safer and more efficient solution for liner installation and removal for AG/SAG/Ball mills, removing people from hazardous zones within your grinding mill. Install your liners by bolting them from outside your grinding mill.

The MillSafe® Bolting System:

Comes in metric and imperial grades of bolts.

Uses the Bradken Spherical Head design for maximum head contact.

Has positive bolt head seating with freedom of movement and self-alignment.

Eliminates point and line loading over traditional oval head bolts.

Fully interchangeable with spherical forged bolt.

MillSafe® Bolting main features:

Superior Design

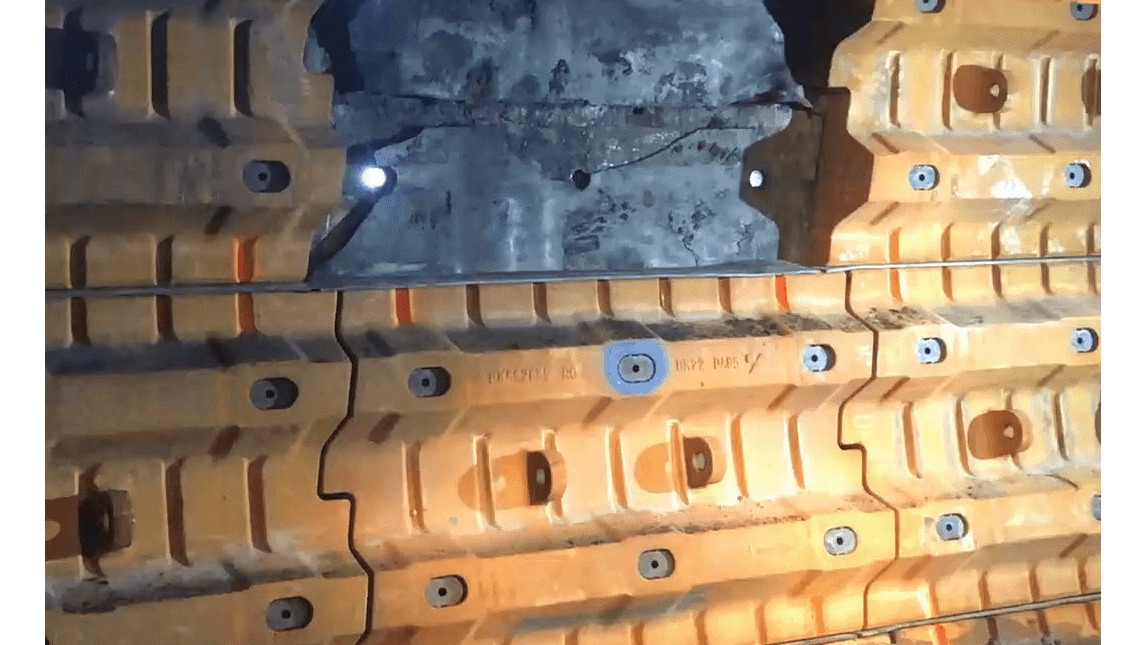

The MillSafe® Bolting System uses the Bradken Spherical Head Bolt design to provide optimal contact between bolt and casting. The bolt hole design also accommodates for misalignment between bolt, liner and mill shell.

Reducing Cost and Increasing Productivity

The Bolting System combined with Liner Location Stripes (LLS) delivers a safer and more efficient liner installation and removal, allowing liners to easily separate from the mill shell once the bolt studs are removed from the outside.

Improved Safety

Improved safety by bolting liners from outside the mill and removing people from the dangerous zones inside a grinding mill during the mill relining process.

Revolutionizing Safety: Bradken's MillSafe™ Bolting System

Bradken pioneers safer mill operations with its innovative MillSafe™ Bolting System. Recently deployed in a nickel mining operation in Western Australia, this system enhances safety and productivity during shell liner installations. By eliminating hazardous manual tasks, it reduces downtime and improves maintenance efficiency.