Wear Solutions

Bradken offers a customised range of abrasion and impact resistant products designed to provide maximum protection for fixed and mobile plant equipment in mining and port operations and conventional oil and gas mining markets.

Our products are made using a wide variety of proprietary materials and are backed by a range of aftermarket support services including remote and laser wear monitoring and maintenance services.

Bradken strives to improve existing technologies and develop new products to provide maximum protection for fixed plant and mobile equipment against the effects of wear. Our research and development has led to Bradken providing a range of products in Abrasion Resistant (Q&T) steel, chromium carbide overlay or cast white iron and ceramic based products. This versatile range allows Bradken to recommend the best material for any application.

Duracast® - Cast White Iron

Bradken offers a range of Cast White Iron solutions.

Duracast N460

Duracast DC17

Vulcabrix® - Ceramic Composites

Bradken offers a range of Rubber Bonded Ceramic solutions. The Vulcabrix range of liners combines very hard abrasion resistant ceramic tiles, with impact absorbing rubber, on to a steel backing plate.

Duaplate® - Wear Resistant Weld Overlay

Bradken offers a range of Weld Overlay Plate solutions. Duaplate® is a well-established weld overlay plate, well known for its high abrasion and impact resistance.

Duaplate® is wear-resistant cladding that is fusion bonded to a backing material. The standard backing material for Duaplate® is mild steel. The backing plate acts as a ductile base, which allows Duaplate® to be formed and shaped without damage to the overlay material. The backing plate can also be used for structural support, allowing entire hoppers and chutes to be created using only Duaplate®. Duaplate® is available in four different grades to suit a range of operating conditions:

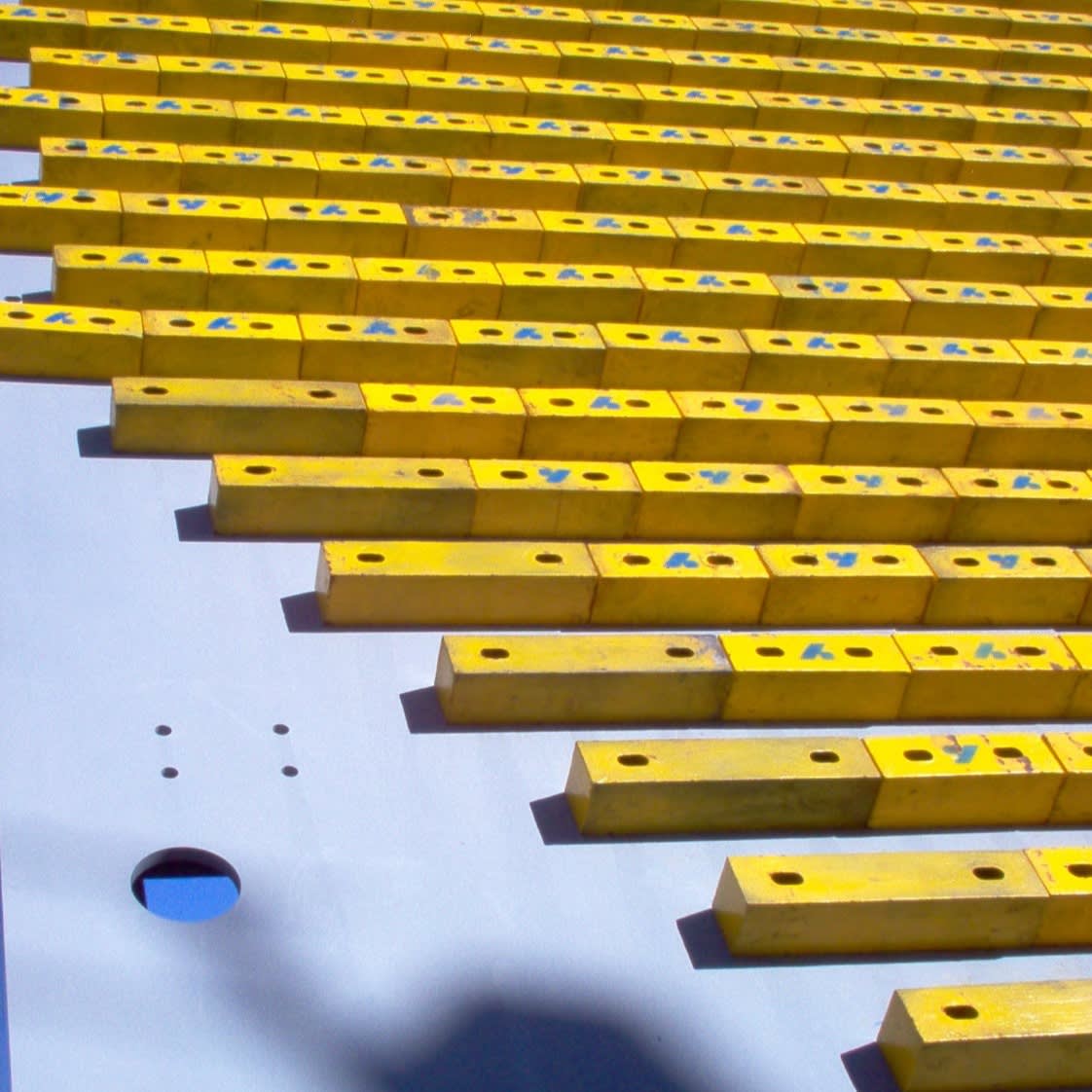

Duablock® - Bi-Metallic White Iron

Duablock® is a composite material used in mining applications experiencing severe wear. This product consists of a white iron casting bonded to a backing plate. Duablock®’s wear resistant microstructure, along with its impact absorbing backing plate, makes it perfect for high abrasion and high impact applications.

Composite White Iron (Duablock)

Other Wear Solutions

Bradken offer a range of additional wear system solutions.

AR Steel Plate (Q&T)

Ceramic Epoxies

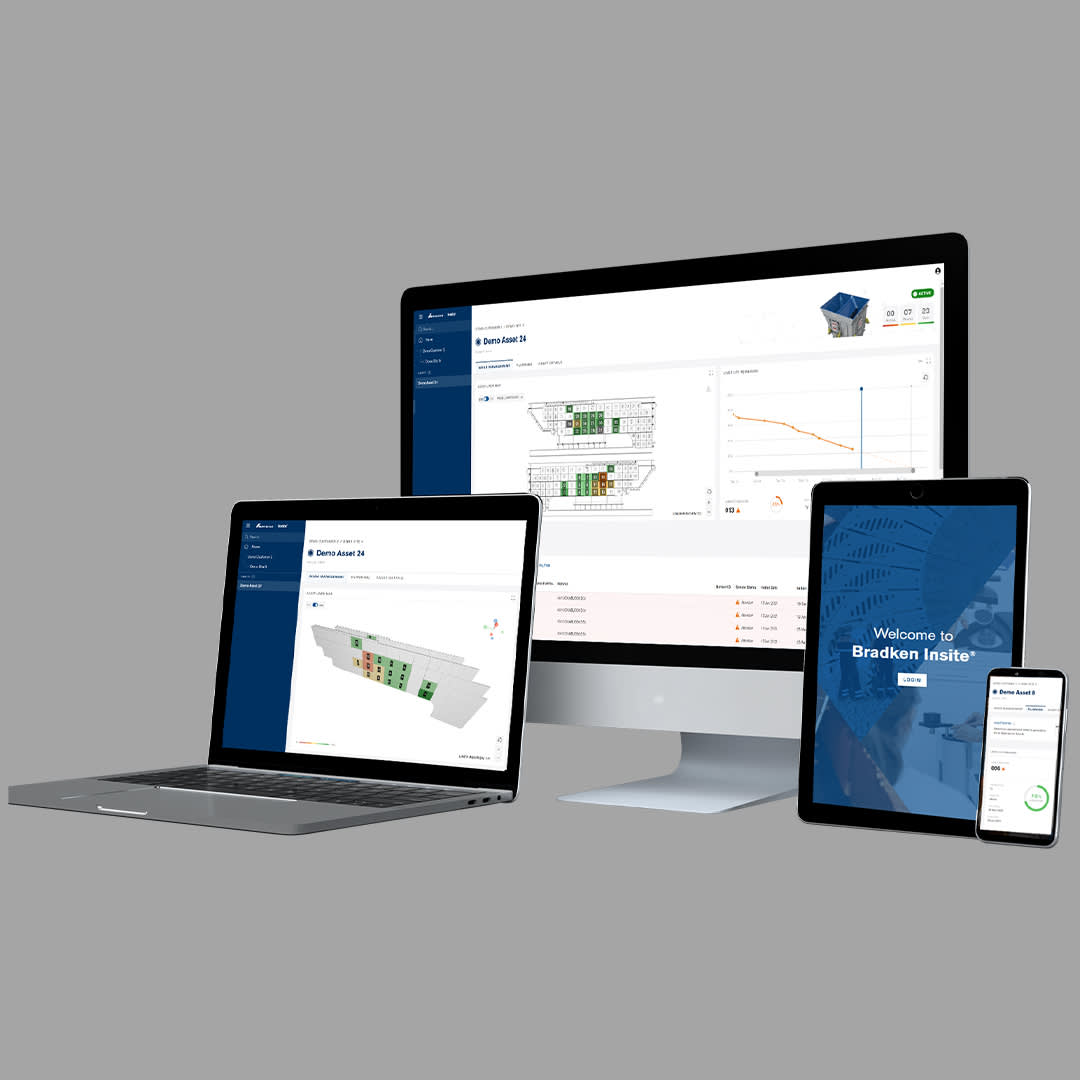

Smartliner® Condition and Performance Monitoring

Bradken SmartLiner®

Remote real-time wear monitoring and wear forecasting of Fixed Plant Assets. The safer and more efficient way to view the condition data of your liners and plan maintenance.

Fixed Plant Product Catalogue

Safer, Faster And Easier Solution

ChuteSafe ™ Bolting System

Bradken’s patented one-sided chute liner attachment solution is now available.

ChuteSafe ™ allows for fastening of liners from the wear side of bulk materials handling assets only - no external access is required.